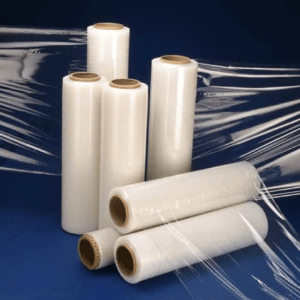

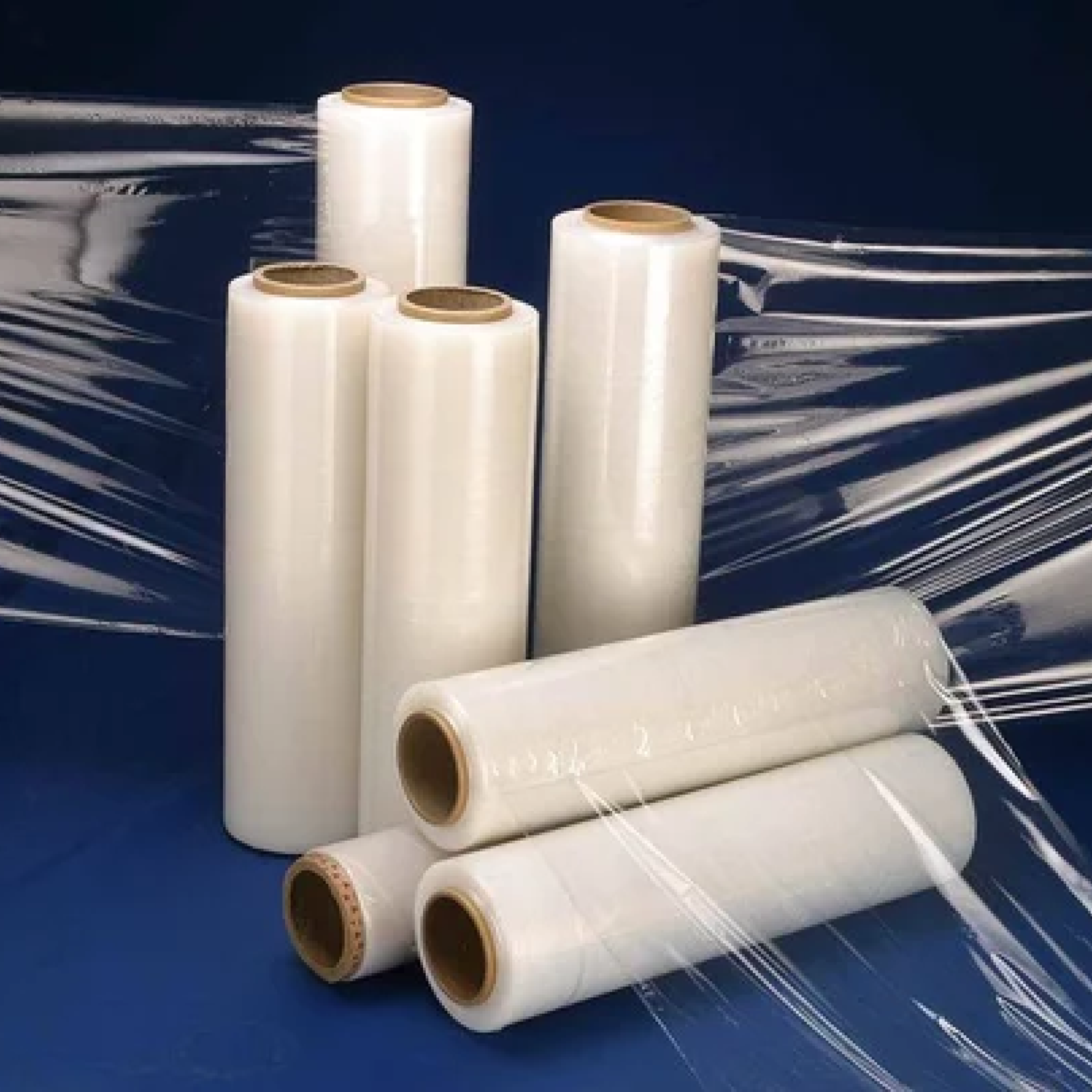

Stretch Film

Wrapping with Strength, Clinging to Quality.

Stretch films are indispensable in the packaging industry, providing a versatile and efficient solution for bundling products securely. These films are primarily used to wrap around products to ensure their stability, protection, and containment during transportation and storage. Depending on the application, there are specific types of stretch films tailored to fit different needs.

Benefits

Enhanced Product Protection Costs

Cost-Effective

Reduced Product Damage

Increased Load Stability

Versatilit

Key Features

Elongation

The ability of the film to stretch without breaking. A higher elongation rate means the film can cover more area or volume with less material.

Thickness

Determines the durability and strength of the film. Films can range from ultra-thin to heavy-duty, depending on the application

Clarity

The transparency of the film, which allows for easy product identification.

Memory

Once stretched, the film’s ability to shrink back to its original state, ensuring a tight wrap.

UV-Resistant

Ability of the film to withstand the damaging effects of ultraviolet rays, especially when products are stored outdoors.

Tear Resistance

The film's capability to resist punctures and tears, even when wrapped around sharp or uneven surfaces.

Types of Stretch Films

Hand Grade Stretch Film

Specially designed for manual application, this film is the choice for businesses that require flexibility in packaging operations.

Machine Grade Stretch Film

Optimized for automated processes, this film is designed for high-speed and consistent wrapping in industrial settings.

Stretch Films Specifications

Specification

Details

| Thickness | Above 50 Micron |

| Width | 250 mm & above |

| Color | Transparent |

| Material | LDPE/ LLDPE |

| Length | 100m Above |

| Processing Type | Cast/ Blown |

| Film Grade | Hand And Machine Grade |

Get In Touch