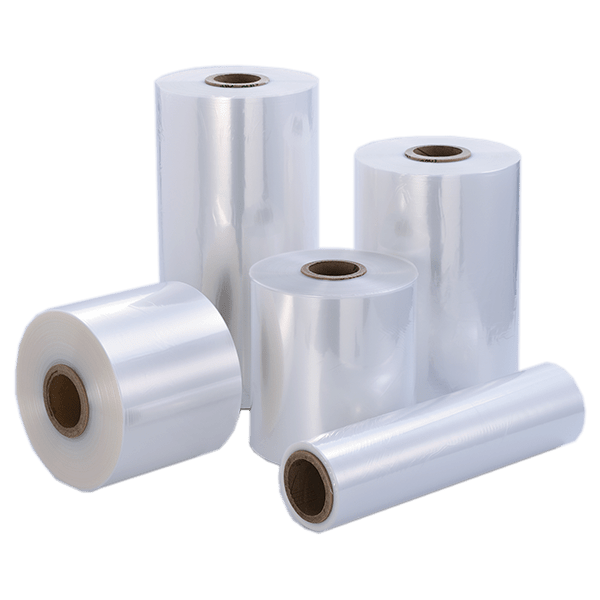

Shrink Film

Reduction in Packaging Material

Shrinking to Perfection, Protecting with Precision.

Shrink films play a pivotal role in the packaging sector, offering a tightly-fitting protective layer over products by using heat. These films, when exposed to a specific temperature, shrink to snugly encase an item, offering both product protection and an aesthetic finish. They are especially popular in the food and beverage sector, among other industries, due to their ability to conform to any product shape.

Benefits

Superior Product Presentation

Durable Protection

Tamper Evident

Space Efficiency

Versatility

Key Features

Shrink Rate

Defines how much the film shrinks in relation to its original size. A higher shrink rate offers a tighter fit.

Seal Strength

Indicates the robustness of the film's sealed areas, ensuring they remain intact during the shrinking process.

Heat Sensitivity

Denotes the temperature range within which the film begins to shrink, ensuring compatibility with various heating systems.

Thickness

Dictates the film's durability and strength. Films might be ultra-thin for lightweight products or more robust for heavier items.

Flexibility

The film's ability to conform to irregular shapes without tearing.

Clarity

High transparency of the film enhances product visibility and presentation.

Barrier Properties:

Some shrink films offer enhanced resistance to oxygen and moisture, making them ideal for certain perishables.

Shrink Films Specifications

Specification

Details

Thickness | 25 microns & above |

Width | 250 mm & above |

Color | Transparent |

Material | LDPE/ LLDPE |

Length | 100m Above |

Processing Type | Blown |

Get In Touch

Types of Shrink Films

Hand Grade Shrink Film

Ideal for businesses with diverse, often smaller-scale packaging needs. Hand grade shrink film can be applied with handheld heat guns, making the process flexible and mobile.

Advantages:

Versatility: Suitable for packaging a wide range of products, especially for small-scale operations.

Ease of Use: Simple to handle and does not require extensive machinery or equipment.

Cost-Effective: Generally cheaper and does not necessitate major capital investment.

Portability: Can be applied in various locations, not restricted to a specific packaging station.

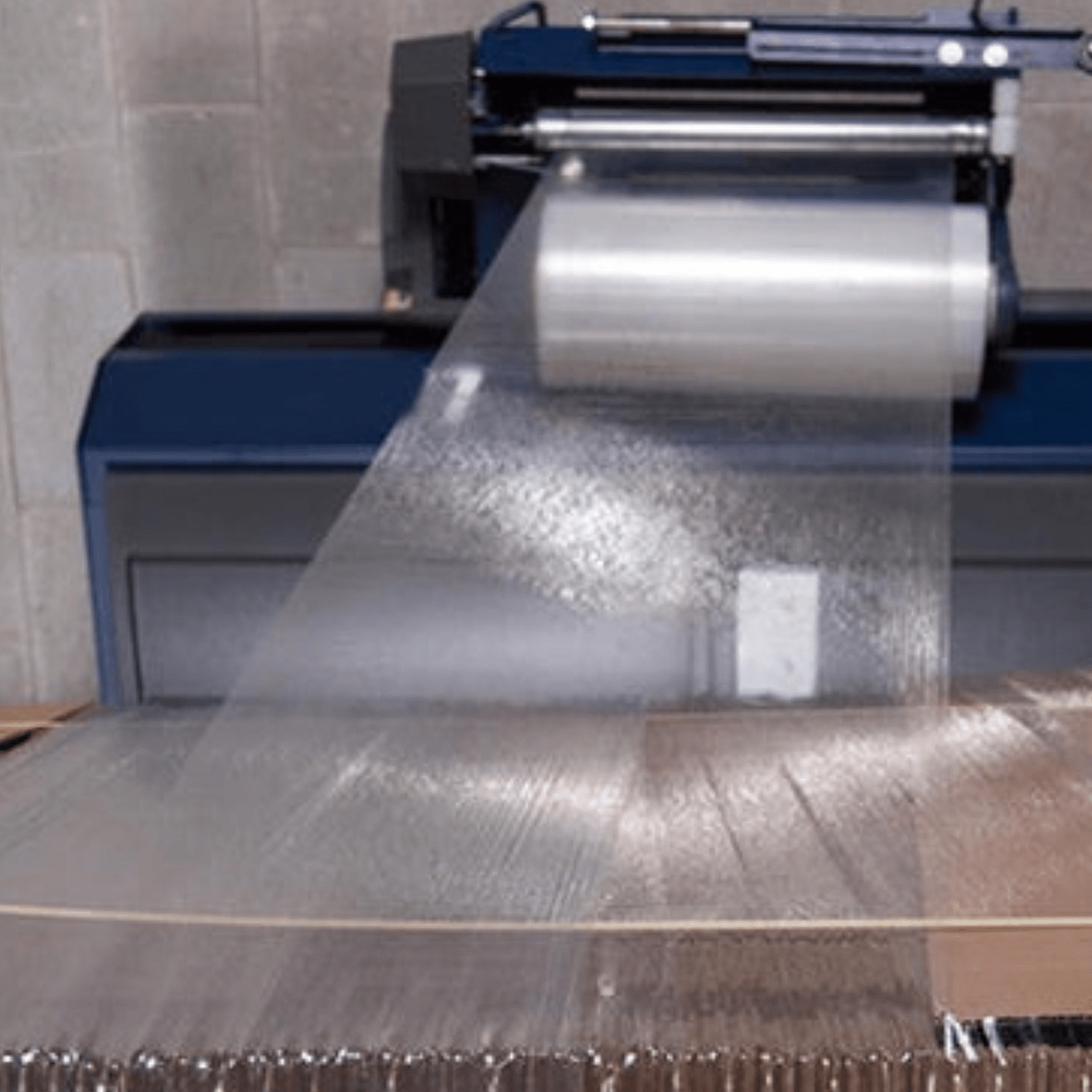

Machine Grade Shrink Film

Designed for large-scale, automated packaging operations. It's optimized for machines that wrap, seal, and shrink products in a streamlined manner.

Advantages:

High-Speed Packaging: Suitable for businesses with large volumes of products to be wrapped in quick succession.

Uniform Finish: Consistent heating ensures a uniformly tight wrap around products.

Enhanced Durability: Engineered to endure the mechanical stresses of automated processes.

Labor Efficiency: Reduces manual intervention, leading to faster packaging and reduced labor costs.